UNO AIR's News

A few months ago, a Japanese agricultural equipment trading company asked us to produce OEM air compressors.

We tested one of their current models, and the results were eye-opening:

-

The “2HP” pump actually produced around 1HP.

-

The “39L” air tank measured only about 32L.

In fact, many manufacturers and sellers display inflated specifications to cut costs.

It’s not uncommon to see 1HP labeled as 2HP, or 7.5HP as 10HP.

That’s why some customers ask,

“Why does Unoair’s 3HP compressor outperform others’ 5HP models?”

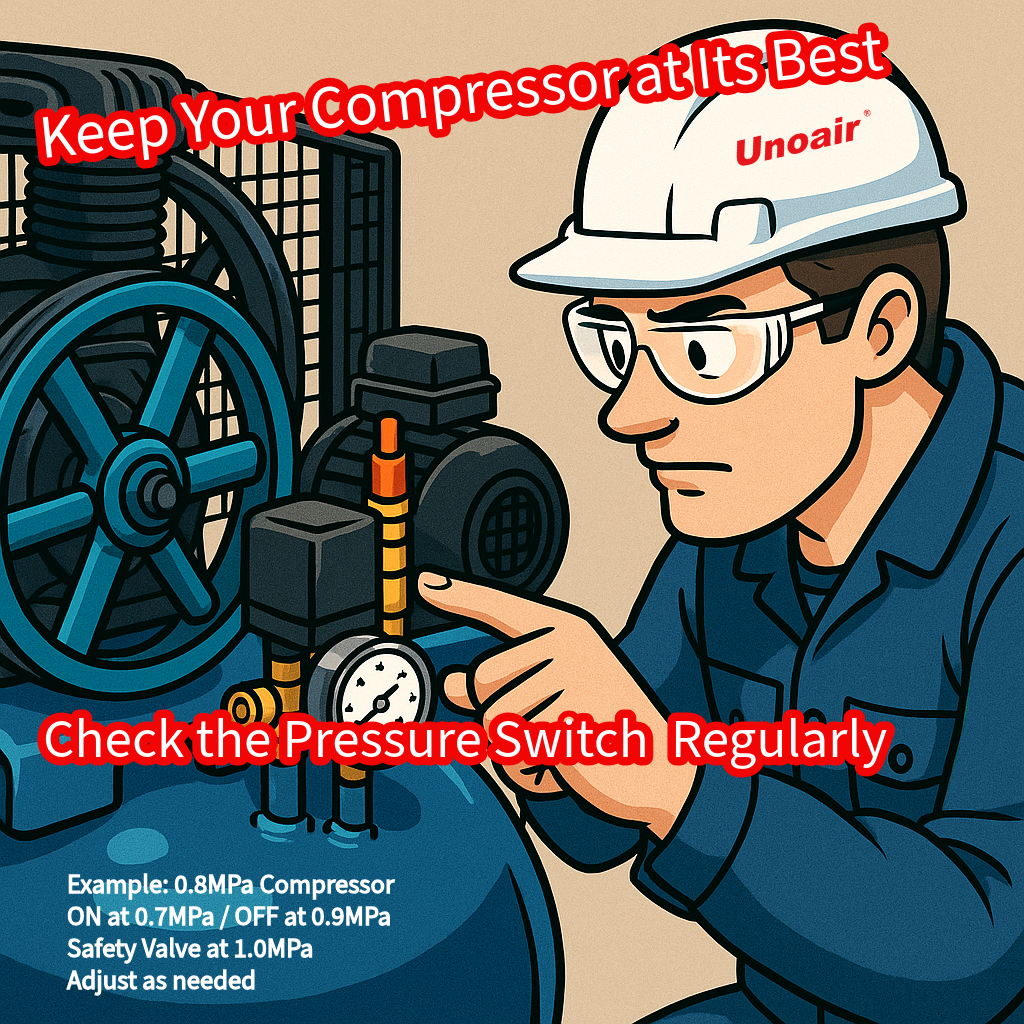

If you rely on accurate performance, it may be worth measuring your compressor’s actual tank capacity and air output.

We received a lot of interest and inquiries about our tools from many customers!

We will continue working on strengthening our sales channels so that we can deliver our products to customers in Japan more quickly.

Tool Japan ご来場ありがとうございました

今回もたくさんのお客様に弊社工具へ関心をお寄せいただき、多くのお問い合わせをいただきました!

これから国内の皆さまに、より早くお届けできるよう販売ルートの整備に努めてまいります。

With a solid strategy in place, we remain highly competitive in the market.

Low quantity orders? OEM or ODM requirements? Challenges in sourcing tools?

Unoair got you covered!

Looking to create your own OEM tools in low quantities?

Want to offer products your competitors don’t have?

Unoair has you covered!

Visit us at Tool Japan and tell us about your needs.

Free Ticket

https://www.jagri-global.jp/tokyo/ja-jp/register.html?code=1442309358255575-BML

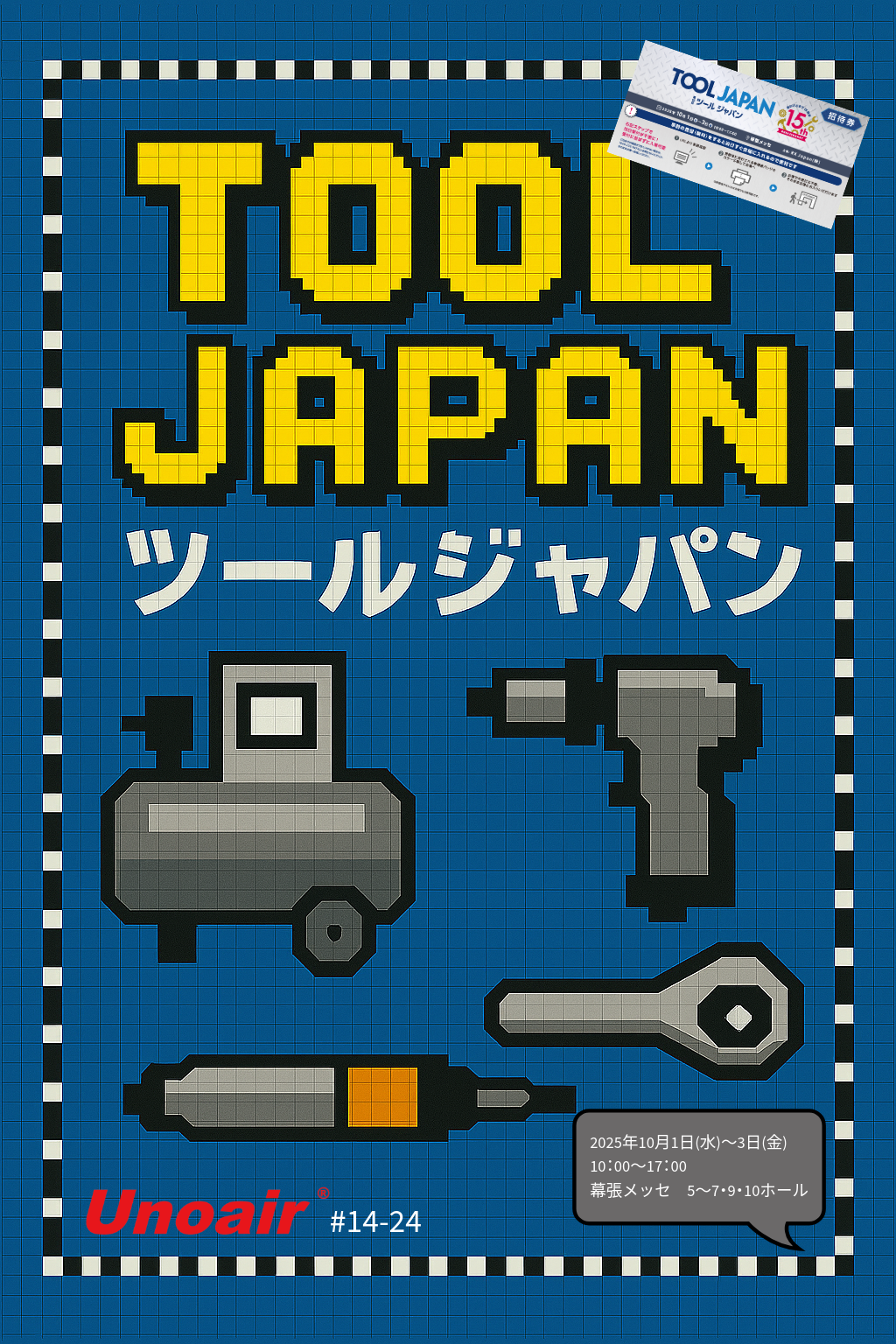

We are excited to showcase our latest air compressors, pneumatic tools, precision torque screwdrivers, and other automotive tools at the following upcoming exhibitions:

-

Tool Japan 2025 – Makuhari Messe, Japan | October 1–3, 2025

-

Canton Fair – Guangzhou, China | October 15–19, 2025

-

WAM West Africa Hardware, Tools & Mechatronics Fair – Lagos, Nigeria | November 11–13, 2025

Our team looks forward to meeting you at these events and sharing our newest innovations.

Free Ticket

https://www.jagri-global.jp/tokyo/ja-jp/register.html?code=1442309358255575-BML