UNOAIR's News

Title:

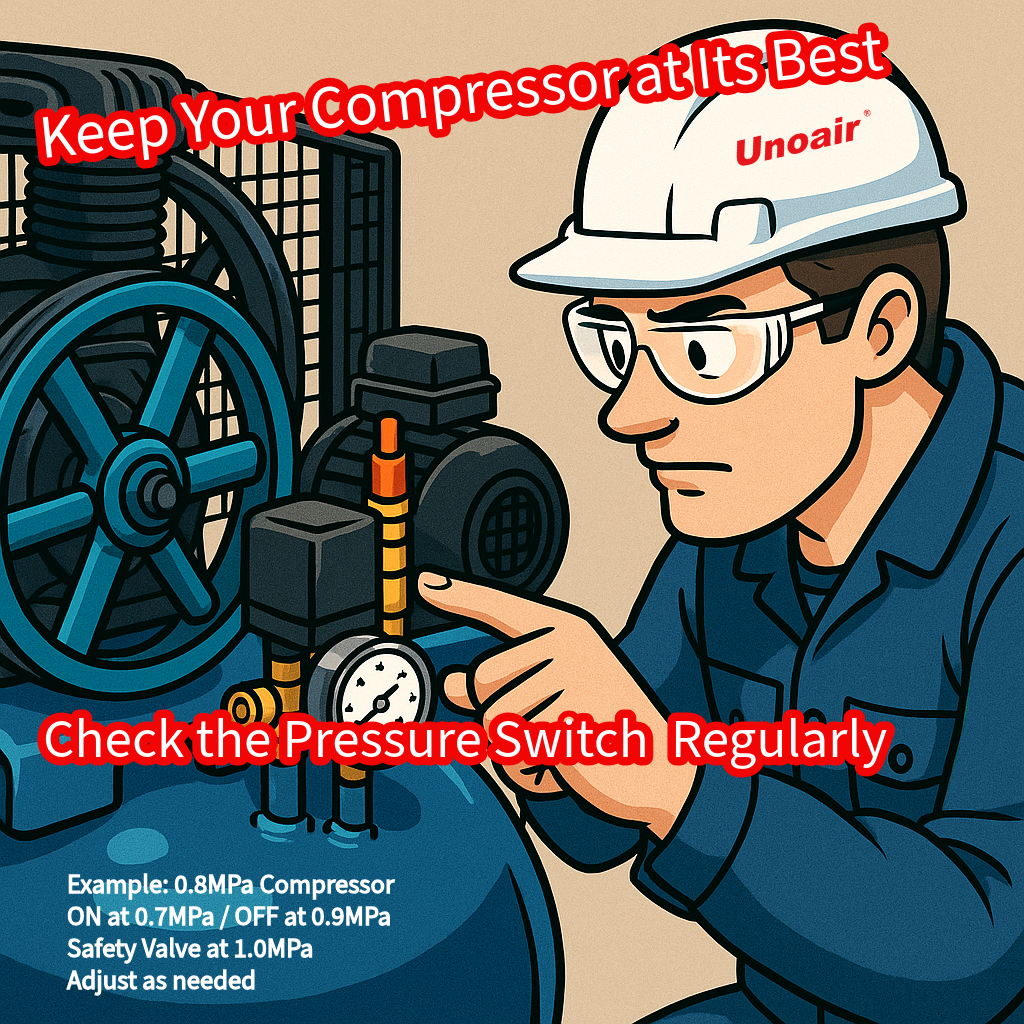

UNOAIR Weekly Update 10/08/2025 Know You Compressor Pressure Switch and Safety Valve

Release date: 2025-10-08

Low output? Frequent startups? Abnormal operation?

Check your pressure switch and safety valve first.

1. Purpose

The pressure switch and safety valve are vital for safe and efficient compressor operation.

Regular inspection prevents pressure-related failures and ensures stable performance.

2. Recommended Inspection Frequency

Normal use: Every 3 months

Heavy use: Every 1–2 months

After long downtime: Inspect before restarting

3. Pressure Switch Inspection

Power off: Always disconnect power and release air before inspection.

Check settings: Confirm ON/OFF pressures match specifications.

(Example: 0.8 MPa compressor → ON = 0.7 MPa / OFF = 0.9 MPa)

Test operation: Observe the pressure gauge to ensure proper stop/start timing.

Inspect terminals: Look for loose wires, corrosion, or dust.

Check internal wear: Replace or adjust worn copper contacts if needed.

4. Safety Valve Inspection

Check pressure: Ensure operating pressure doesn’t exceed the set limit (≈ 1.0 MPa).

Test manually: Lift the valve slightly to confirm air release.

Replace if stiff or unresponsive.

Check for leaks: Make sure no air leaks when the valve is closed.

Confirm setting: Set pressure should match the compressor’s max working pressure (typically 1.0 MPa).

5. Precautions

Always turn off power before inspection or adjustment.

Stop using the compressor if any abnormality is found and contact a qualified technician.

Keep inspection records for maintenance tracking and warranty support.